Reconfigurable Robots

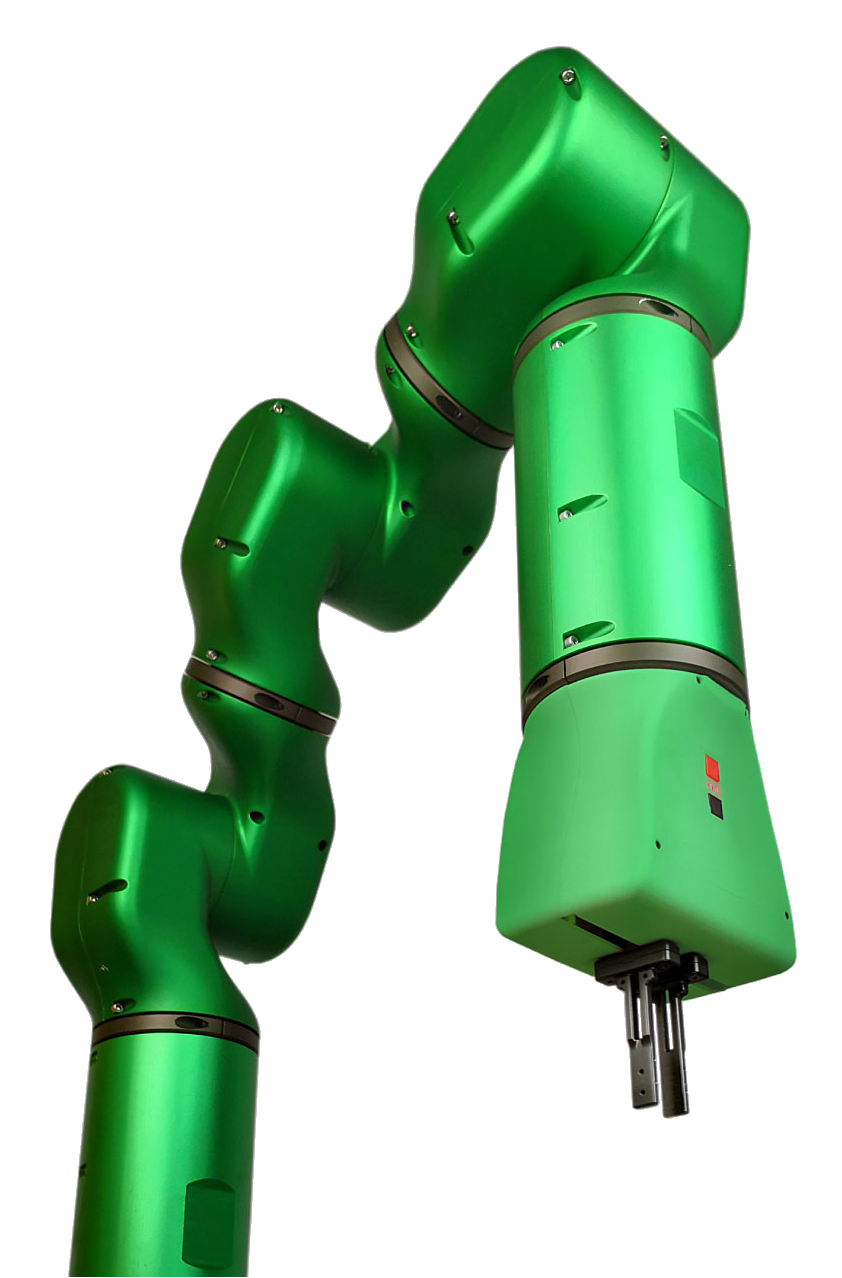

Alberobotics reconfigurable hard- and software systems are natively developed to be reconfigured within minutes. They can be flexibly adapted or even entirely repurposed for varying industrial applications.

MODULAR WAS YESTERDAY, RECONFIGURABLE IS NOW

Conventional Robots are members of a carefully developed product line-up. Each robot in this line-up adresses a certain range of applications. Its shape and properties remain fixed for the entire robot life.

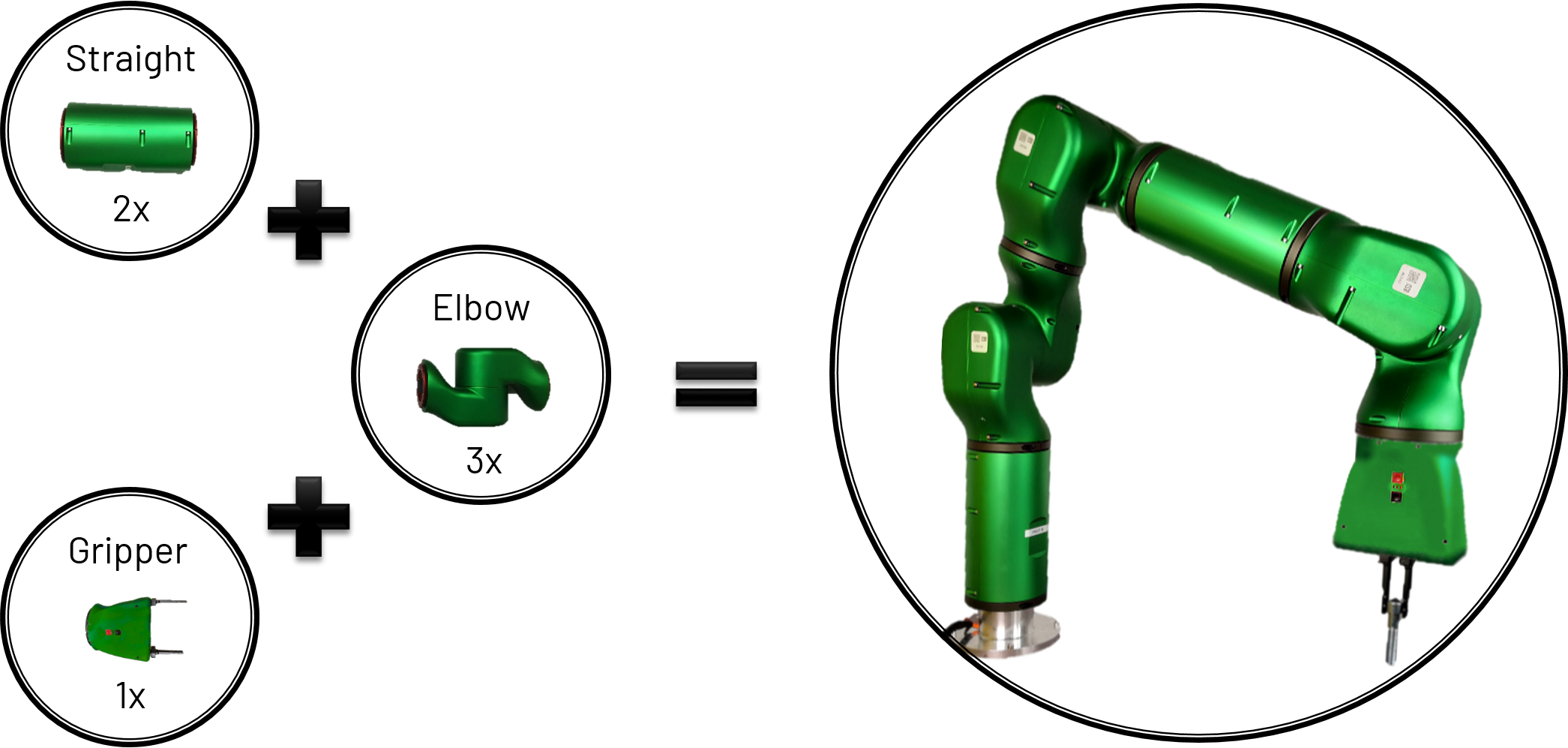

Modular Robots, rather than being part of a fixed product line-up, are customized by combining standard components. They can be tailor-made with low effort for even niche applications, serving those purpose for their entire life time.

Reconfigurable Robots are neither part of a fixed product line-up nor do they serve only a single purpose for their entire life time. While they are also composed of standard modules, these modules are explicitly designed to be frequently and rapidly connected or disconnected. They are intentionally made to be recombined with other modules in different applications and for different purposes.

Few Modules, Endless Solutions

-

Zero Lines of Code

Alberobotics modules recognize and configure themselves. Hand-guiding and interactive adaptation replace writing any line of code. This facilitates the co-creation of solutions by the integrator and the End-User.

-

Swap & Return

Anyone capable of assembling an IKEA shelf can exchange the modules due for maintenance. No need to for an on-site service technician. Swap them within a minute and return them to us.

-

Tailor-Made for You

Alberobotics modules enable the integrator to rapidly tailor customized long-reach or low-profile, ample strength or highly dexterous robots fitting any environment. Faster deployment at lower cost.

-

Plug & Play

If the task changes, so does the Alberobotics solution. The plug & play hardware are reconfigured within a few minutes. Software modules reconfigure themselves and the system responds to the new requirements.

-

Pay Per Use

Alberobotics modules lend themselves to pay per use and subscription based distribution models, which lower the financial risk for the end-user and simplifies the ROI calculation.

BUILD, RUN, ADAPT, REPEAT

In the offline approach, a user sets up a robot with our reconfigurable modules in the virtual environment of our Alberobotics Composer Studio. The user selects modules from a library, assembles them toform a mechanism that is immediateley visualised in 3D.

The more pragmatic user might prefer an online approach to assemble the robot from real physical modules. This gives more immediate impression of the size and shape of the mechanism. Potentially this user also directly assembles the modules in the eventual operating environment and sees how it fits without modelling the entire workplace in CAD.

No matter which approach a user might select, the workflow is the same. Once the user has assembled a set of modules in a desired configuration, our Operating System automatically reconfigures the entire software architecture on-the-fly, generating mathematical models of both the robot kinematics and dynamics and updating the controller architecture.